Gaining insight into your customers is essential for segmenting your consumer base and marketing your products effectively. In the fashion industry data is recordable from every part of the business, supplying significant insight into buyer behaviour, market trends and in-depth profiling of your customers.

In the world of fast fashion, apparel companies must move quickly to react to trends and adapt their offering to suit consumer preferences which change constantly.

Data is the key to this information, but to analyse and transform data into useful, meaningful insights, manufacturers need a system that can process vast amounts of data quickly and efficiently. This technology comes in the form of ERP software, which provides big data and analytics in the fashion industry.

Collecting the Data

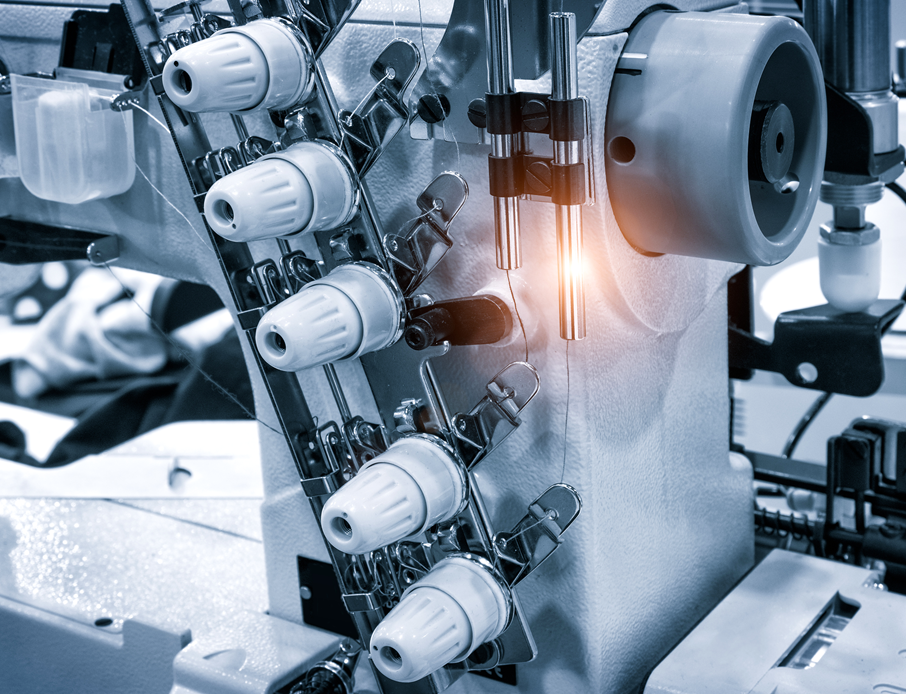

Data can be recorded from almost every point in the production process, so apparel manufacturers can collect vast amounts of data in a short time frame. This could include data sets collected from orders, production, delivery, supply chain, material purchasing, and sales.

Apparel ERP software allows you to capture and record these types of data sets automatically from the point of data entry from either the business or the customer, depending on the process.

Software can also be connected to IoT (Internet of Things) devices to help in the data collection process.