For years, distributors have acted as intermediaries between manufacturers and consumers by managing the movement of goods from one party to another. However, manufacturers and retailers are beginning to establish their own distribution networks to cut costs and gain market dominance.

The future of distribution is left uncertain as distributors struggle to sustain profitability and their position within the market. Therefore, the wholesale and distribution industry has seen a rapid increase in the adoption of digital technologies to manage and handle the ever-growing needs of their customers.

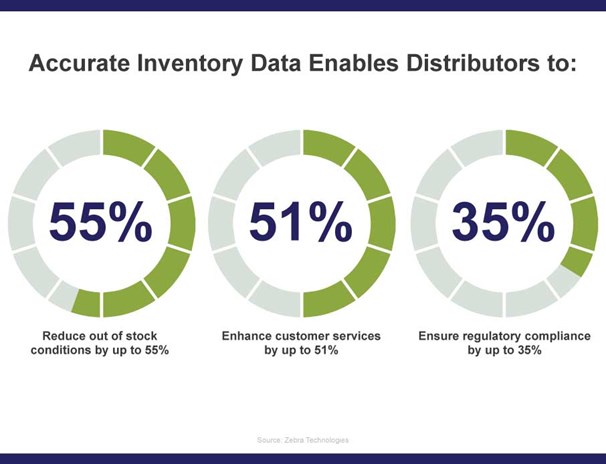

Digital technologies have allowed distribution and wholesale companies to expand their capabilities and are achieving reductions in costs, improved processes, increased sales growth, better-quality customer service and customer reach.

In this blog, we look at the challenges facing modern distributors that can be helped with digital technology, including artificial intelligence and machine learning, IoT, real-time data visibility and automation.

What are the challenges facing the modern distributor?

Key areas of the distribution process are hindering the effectiveness of operations and their ability to compete in a highly demanding market, they are:

- Inventory management

- Demand forecasting

- Customer service

- Data visibility

Did you know?