Product Configuration

All the tools you need, in one convenient place

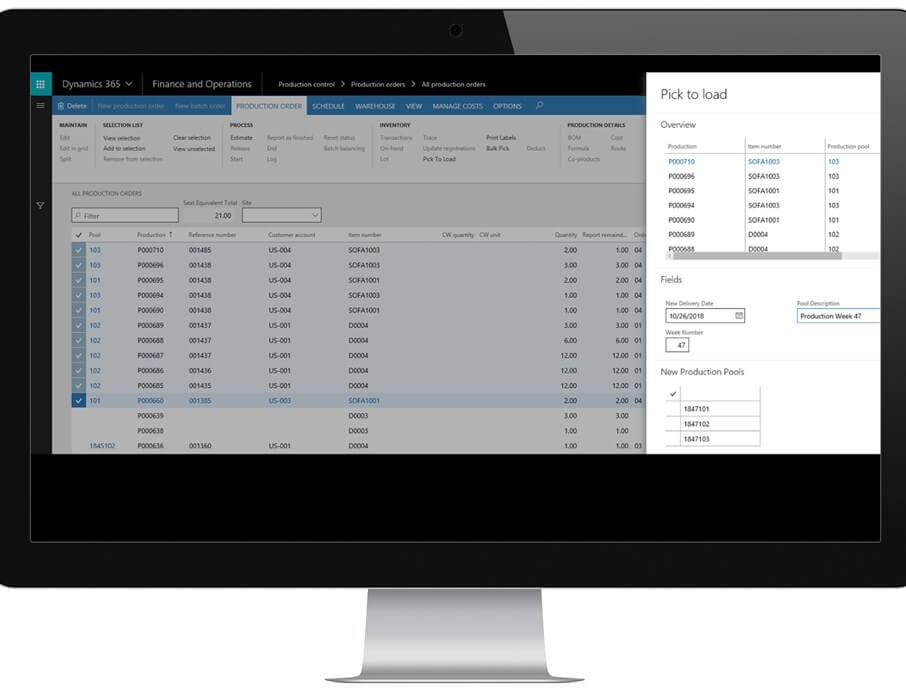

In Make-to-Order (MTO) manufacturing, products are configured when an order is placed and the various product options have been chosen. Syscom 365 enhances the capabilities of the Microsoft Dynamics 365 configurator. Once an order has been placed, the system automatically calculates a price based on the chosen criteria, taking into account the materials used and the custom variations chosen by the customer.

The product configurator reduces any risk that comes with assembling a made-to-order product. The risk is reduced by automatically creating works orders in-line with the delivery schedule and creating BOM and routing instructions, all based on the product configured. The benefit of this is that returns and reworks are reduced, improving profit margins and customer satisfaction.

Syscom 365’s product configurator offers unlimited product variations and combinations, making it particularly useful for custom manufacturers offering numerous product customisation options. It deals with any option of choice – colour, style, length, size, material-specific parts etc.

The product configurator also aims to reduce the time from sale to production by automating key processes relating to ordering, assembly, output and delivery.

The benefits of product configuration software for custom manufacturing